Understanding Flexible Wire Manufacturing

In the realm of electric components, one name that resonates with flexibility and adaptability is Flexible Wire Manufacturer. Flexible wires play a crucial role across various industries, enabling efficient power transmission and contributing to the functionality of countless devices. In this section, we explore what flexible wire is, its defining characteristics, and the differences in the manufacturing processes that produce it.

What is Flexible Wire?

Flexible wire, as the name implies, is designed to bend, twist, and adapt to different shapes without breaking. It is typically constructed using multiple strands of metal—most often copper or aluminum—bundled together to provide both conductivity and flexibility. This design allows flexible wires to be used in applications where movement and space constraints are common, such as in robotics, automotive wiring, and electronic devices. Flexible wires are not only vital for internal wiring but also for applications that require frequent movement, such as in retractable charging cables or mobile devices.

Key Characteristics of Quality Wire

When evaluating flexible wires, several key characteristics determine their quality and applicability:

- Stranding: High-quality flexible wires feature finer strands that enhance flexibility and reduce the likelihood of wire breakage.

- Conductor Material: Copper is the most commonly used material for optimal conductivity, although aluminum is lighter and more affordable for certain applications.

- Insulation: The wire should have durable insulation that withstands heat, moisture, and environmental factors, thus ensuring safety and longevity.

- Gauge: The wire gauge indicates the diameter of the wire and directly affects its current-carrying capacity—an essential factor for various applications.

- Temperature Rating: Each flexible wire type comes with temperature ratings that determine its operational safety limits.

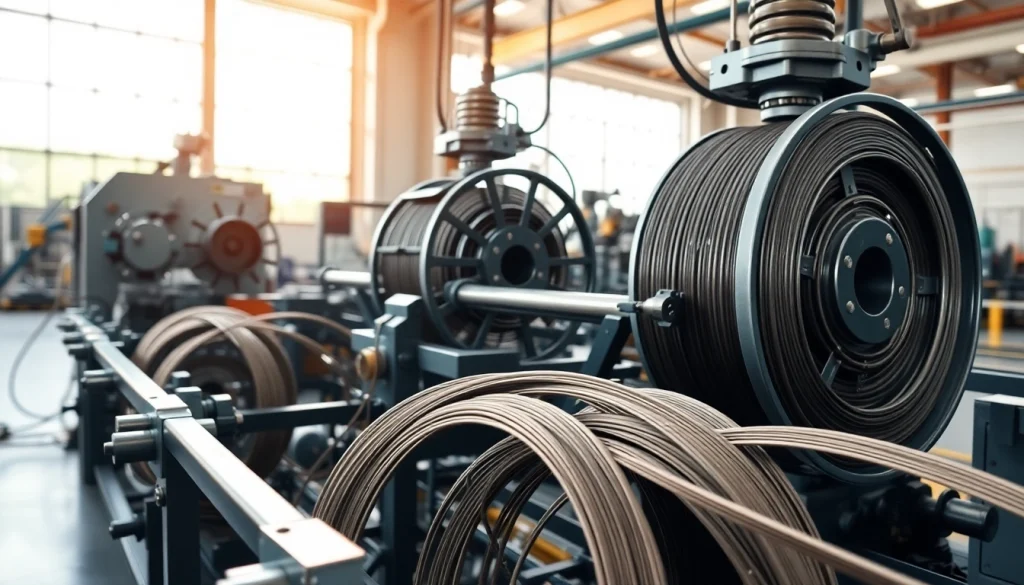

Differences in Manufacturing Processes

The manufacturing of flexible wire can differ significantly based on the intended use and specifications. Here are some common methods:

- Stranding Process: Involves twisting together multiple strands to form a single wire, enhancing flexibility.

- Extrusion: This process applies a continuous flow of material through a die to produce insulation layers around the conductive cores.

- Tinning: A coating of tin is applied to the copper wires to improve solderability and prevent oxidation.

Different manufacturers may employ variations of these processes tailored to the specific application requirements of their clients, further emphasizing the importance of selecting a high-quality manufacturer.

Benefits of Partnering with a Reliable Flexible Wire Manufacturer

Choosing a dependable flexible wire manufacturer can significantly impact the efficiency and quality of your end products. Let’s delve into some key benefits that come with this partnership.

Enhanced Performance in Various Applications

Quality flexible wires are engineered for optimal performance in their designated applications. A reliable manufacturer understands the rigorous demands of industries such as telecommunications, automotive, and consumer electronics, thus providing wires that exceed standard performance metrics. This performance translates into enhanced reliability and functionality of the end products, making them more appealing to customers.

Long-Term Cost Efficiency

Investing in quality flexible wire from a reputable manufacturer leads to long-term cost efficiency. Quality wires typically have lower failure rates and decreased maintenance costs. Furthermore, a well-constructed flexible wire can improve overall system performance, translating to lower energy costs over time. When evaluating manufacturers, assessing their long-term reliability can guide you toward saving significant amounts in the future.

Customization Options for Specific Needs

Every application may have unique requirements, and a trustworthy flexible wire manufacturer should offer customization options. This could include variations in gauge, insulation type, strand configuration, and even color coding for identification purposes. Such adaptability ensures that the wires meet precise demands, leading to better integration and performance in complex systems.

Choosing the Right Flexible Wire Manufacturer

With numerous manufacturers claiming to provide the best flexible wires, making an informed decision can be daunting. Here are crucial factors to consider in your selection process:

Evaluating Experience and Expertise

Experience matters when it comes to flexible wire manufacturing. Choose a manufacturer with a proven track record in producing a variety of flexible wires tailored to specific industries. Assess their expertise in material properties, production techniques, and industry standards; these factors indicate their capability to meet rigorous demands.

Assessing Quality Control Measures

Quality control is vital to ensuring that the wires meet required specifications. Look for manufacturers that have stringent quality assurance protocols in place, including inspection processes and testing methods. ISO certifications and UL listings can also indicate adherence to high standards of quality and safety in wire manufacturing.

Customer Support and After-Sales Service

A responsive and knowledgeable customer support team is crucial when dealing with potential wire issues or queries. Choose a manufacturer who commits to excellent after-sales service, providing support throughout your project’s lifecycle. A strong relationship with the manufacturer can facilitate problem resolution and improve production processes.

Applications of Flexible Wire in Different Industries

Flexible wires are integral to a wide range of industries, owing to their versatility and reliability. Below are applications across various sectors:

Electrical and Electronics

In the electrical and electronics industry, flexible wires connect components in various devices. Whether in consumer gadgets like smartphones or in larger systems such as computers and appliances, these wires ensure effective power distribution and data transmission. Their ability to bend without compromising connectivity makes them a favorite among engineers and designers.

Automotive and Aerospace

Flexible wires are essential in the automotive and aerospace industries, where they are used for electrical systems, lighting, and infotainment apparatus. As vehicles become more technologically advanced, with integrated intelligent systems, the demand for reliable and adaptable wiring solutions continues to grow. The lightweight nature of flexible wires also contributes to enhanced fuel efficiency and operational performance.

Construction and Engineering

In construction and engineering, flexible wires play a pivotal role in connecting machinery and infrastructure. From construction sites to HVAC systems in large buildings, effective wiring solutions ensure operational safety and efficiency. Structural adaptability and easy installation in confined spaces further enhance their suitability for this sector.

Future Trends in Flexible Wire Manufacturing

As technology advances, the flexible wire manufacturing industry is poised to evolve significantly. Here are some emerging trends to keep an eye on:

Innovations in Material Science

Research in material science is continually pushing the boundaries of flexible wire manufacturing. New materials that provide better conductivity, enhanced flexibility, and resistance to environmental factors are being developed. Nanotechnology, for instance, is being explored to create wires that can withstand extreme conditions while maintaining efficiency.

Automation and Smart Manufacturing

The rise of automation in manufacturing is revolutionizing the production of flexible wires. Smart factories equipped with AI and IoT technologies enable real-time monitoring and adjustments during manufacturing. This not only improves efficiency but also ensures continuous quality control, resulting in higher-quality flexibility and performance in final products.

Sustainability Practices in Production

With increasing awareness of environmental practices, manufacturers are increasingly adopting sustainability in their production processes. This includes utilizing recyclable materials, reducing waste, and optimizing energy consumption during manufacturing. Embracing sustainability is becoming essential to meet consumer demand for environmentally responsible products.

Frequently Asked Questions

What materials are commonly used in flexible wire manufacturing?

Flexible wires are usually made from copper, aluminum, or other conductive metals, allowing for flexibility and conductivity in various applications.

How do I determine the right wire gauge for my project?

Choosing the correct wire gauge depends on the electrical load, distance, and application requirements. Consult specifications and charts for guidance.

What are the benefits of using flexible wire over rigid wire?

Flexible wire is easier to install in tight spaces, can withstand movement and bending, and is better suited for applications requiring mobility and adaptability.

Can flexible wire withstand high temperatures?

Yes, but it depends on the materials used. Look for flexible wires specifically rated for high temperatures, often found in automotive and industrial applications.

How can I ensure quality when selecting a flexible wire manufacturer?

Check the manufacturer’s certifications, customer reviews, production practices, and quality control measures to ensure reliable and high-quality outputs.